Maximizing Space With Vertical Warehouse Material Handling

Are you running out of floor space in your warehouse? You’re not alone. Most warehouse managers face this challenge as inventory demands grow while real estate costs continue to climb. To find an effective solution, you have to start thinking vertically.

Vertical warehouse material handling transforms your unused overhead space into valuable storage real estate. With this helpful guide, you’ll learn how to maximize space with vertical warehouse material handling.

Benefits of Vertical Storage

Implementing vertical storage solutions in your warehouse can deliver numerous benefits, significantly impacting both efficiency and profitability. By maximizing the unused vertical space in your facility, you can increase storage capacity without the headache of expensive expansions or new construction. With this approach, you’ll reduce overhead costs while streamlining inventory organization.

Additionally, modern vertical storage solutions, such as automated vertical lift modules (VLMs) and high-density shelving systems, enhance workplace safety immensely. These solutions minimize the need for employees to reach, climb, or use ladders frequently.

Also, they support improved inventory accuracy through integrated technologies like barcode scanning and inventory management software. Ultimately, vertical storage solutions enable you to optimize your warehouse operations, reduce costs, and create a more efficient and secure working environment.

Multilevel Mezzanine Systems

Mezzanine systems create additional floor space by building upward within your existing structure. These steel platforms effectively double or triple your usable area without requiring expensive building expansions.

You can customize mezzanine systems to accommodate workflow needs. Incorporate additional picking areas, office spaces, or storage zones. The platforms will integrate seamlessly with your current warehouse storage equipment , allowing forklifts and other machinery to operate on multiple levels.

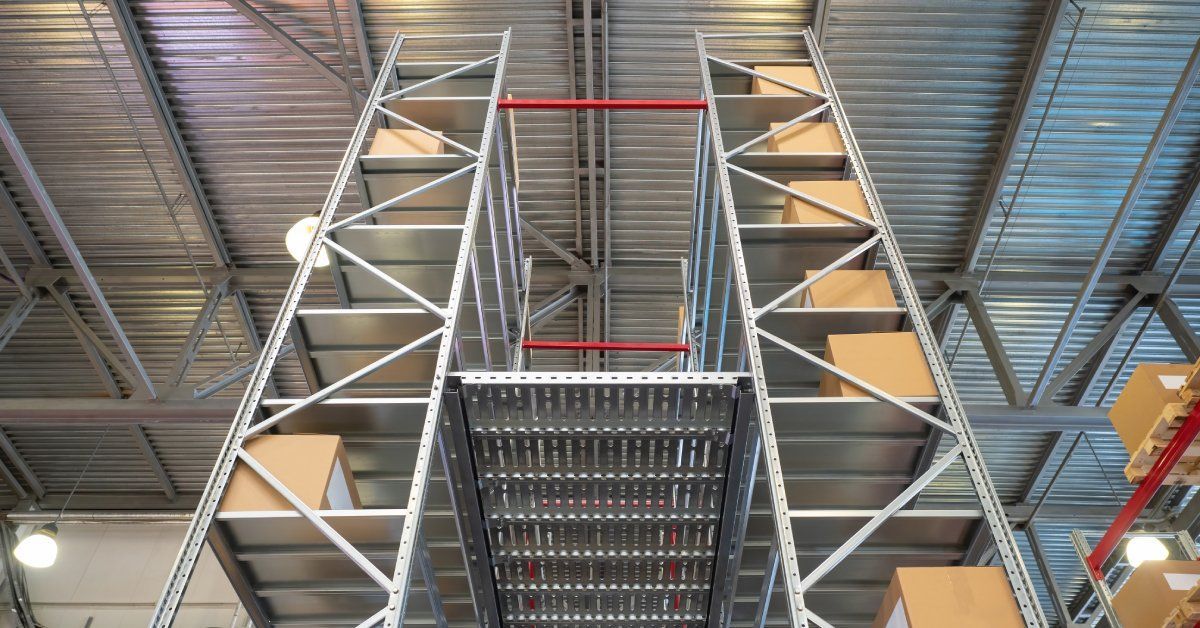

High-Density Pallet Racking

Pallet racking uses only a fraction of your warehouse’s vertical potential, while high-density systems extend upward to maximize cubic storage and maintain accessibility.

Drive-in and drive-through racking systems eliminate aisles between rack rows, allowing you to store more pallets in the same footprint. On the other hand, push-back racking provides excellent density while maintaining selectivity for fast-moving items.

When selecting high-density options, consider your inventory turnover rates. Products with slower turnover work well in deeper storage configurations, while faster-moving items benefit from more accessible positions.

Automated Storage and Retrieval Systems (AS/RS)

AS/RS technology takes vertical storage to new heights—literally. These computer-controlled systems can reach heights of 100 feet or more while maintaining precise inventory control and rapid retrieval times.

The automated cranes operate in narrow aisles, maximizing storage density while minimizing the space required for material handling equipment. You’ll reduce labor costs while improving accuracy and safety in high-storage areas.

Mini-load AS/RS systems work particularly well for smaller parts and components, while unit-load systems handle full pallets efficiently. The investment pays off through improved productivity and space utilization.

Vertical Lift Modules (VLMs)

Rather than sending operators to retrieve items, VLMs bring storage to the operator. The enclosed systems use vertical space efficiently while protecting inventory from dust, theft, and damage.

The automated trays store items at varying heights within the module, and the system delivers the correct tray to an ergonomic access opening. It eliminates the need for climbing, reaching, and searching through multiple storage locations.

VLMs work exceptionally well for small parts, tools, and maintenance supplies. You’ll save additional space compared to traditional shelving. Plus, you’ll improve picking accuracy and decrease labor time.

Cantilever Racking for Long Items

Long, bulky items, such as lumber, pipes, and steel beams, require specialized vertical storage solutions. Cantilever racking extends arms from vertical columns, providing unobstructed access to lengthy materials.

The open design allows you to store items of varying lengths on the same structure while maintaining easy access with forklifts or cranes. Plus, you can adjust arm positions to accommodate different inventory sizes and weights.

Double-sided cantilever systems maximize space efficiency by providing storage on both sides of the structure. This configuration works particularly well in warehouse centers with high ceilings and adequate aisle space.

Narrow Aisle Racking Systems

Narrow aisle configurations reduce aisle widths from 12 to 13 feet to as little as 5 to 6 feet, reclaiming valuable floor space for additional storage. Specialized narrow aisle forklifts operate efficiently in these confined spaces.

Very narrow aisle (VNA) systems push this concept further, using aisles as narrow as four to five feet with wire-guided or rail-guided forklifts. The guided systems ensure precise operation while maximizing safety in tight quarters.

You’ll need to invest in specialized equipment, but space savings typically justify the cost within 2 to 3 years. The increased storage capacity can delay or eliminate the need for facility expansion.

Mobile Racking Systems

Mobile racking eliminates fixed aisles by mounting entire rack sections on wheeled bases. You create an aisle only when needed, which maximizes the space available for storage.

The system works particularly well for archive storage, seasonal inventory, and slow-moving products where immediate access isn’t critical. Electric or manual operation moves the rack sections along floor-mounted rails.

Compression ratios of 2:1 are common, meaning you can double your storage capacity in the same footprint. Often, the investment pays for itself through increased inventory capacity and improved space utilization.

Overhead Storage Solutions

The warehouse ceiling offers valuable storage real estate, but many managers overlook this space. Overhead systems suspend storage platforms, conveyor systems, or rack structures from the building’s structural elements.

Ceiling-mounted platforms work well for seasonal items, spare parts, or slow-moving inventory that doesn’t require frequent access. The space below remains available for regular operations and fast-moving products.

Overhead conveyor systems move products vertically between levels, reducing floor-level congestion while maximizing throughput. These systems integrate well with automated sorting and distribution operations.

Vertical Solutions That Work for Your Warehouse

Maximizing space with vertical warehouse material handling requires you to determine your goals and hire professional expertise. The building’s structure, the equipment’s load capacity, local fire codes, and the facility’s existing systems will all affect installing vertical warehouse solutions. Professional installation is the key to following safety guidelines and establishing high-performance equipment. In fact, many vertical systems require specific structural modifications. This is just another reason why professional assistance is necessary.

Tyler Supply Company specializes in maximizing warehouse operations’ vertical space. Contact us today to start transforming your warehouse’s unused vertical space into valuable storage capacity.